Int. J. Life. Sci.

Scienti. Res., 4(6): 2111-2115, November 2018

Growth

Curve Analysis of Rhizobium leguminosarum Using Voltage Produced by

Microbial Fuel Cell

Shrirang R. Maddalwar1*, Dr. Arti S. Shanware2

1Student, Department of Biotechnology, Rajiv Gandhi Biotechnology

Centre, Nagpur, India

2Director, Department of Biotechnology, Rajiv Gandhi Biotechnology

Centre, Nagpur, India

*Address for Correspondence: Mr. Shrirang R. Maddalwar, Student,

Department of Biotechnology, Rajiv Gandhi Biotechnology Centre, Nagpur-440020,

India

ABSTRACT - Microbial fuel cells could be used to

the study growth rates of aerobic microbial species on the basis of voltage

produced by them in the microbial fuel cell assembly. A fresh culture of Rhizobium

leguminosarum was added in the anode chamber of a microbial fuel cell

assembly and subsequent voltage produced by it was recorded after every fifteen

minutes. The 24 ml/hr of air was pumped in the anode chamber to maintain the dissolved

oxygen level and resistance of 12 ohm was applied across the electrodes. This

process was studied in triplicates and voltage data was recorded. The graph

plotted of voltage against time suggested the growth curve of the species in

the microbial fuel cell system. It was found that voltage gradually increased

with time ranging from 50 mV to 190 mV with a supply of oxygen in the anode,

but it declines gradually to zero in absence of aeration with time and

depletion of nutrients.

Keywords- Rhizobium leguminosarum,

Exo-electrogenesis, Microbial fuel cell, Sporulation, Proton

exchange membrane

INTRODUCTION- It is really difficult task to study metabolic activities of a

single bacterial cell, hence in order to avoid this problem the culture is

usually manipulated in such a way that all the cells of culture should be

showing same metabolic activities. This method is very useful in physiological

studies and also known as synchronous culture method [1-3]. A study

of these cells would enable one to postulate the sequence of events occurring

in a single cell during the process of sporulation [4]. Though this

method is very effective to study the metabolic activities of Rhizobium leguminosarum but

it fails to convey the required information when the culture is not synchronous

[5].

A Microbial Fuel Cell (MFC)

is a device that converts chemical energy from bio-convertible organic

substrate, directly into electrical energy through the metabolic activity of

microorganisms. A simple MFC setup contains two chambers respectively anode and

cathode separated by Proton Exchange Membrane (PEM). The microorganisms are

inoculated in an anodic chamber, where they oxidize the substrate and generate

protons and electrons. The electrons are transferred from anode to cathode

through the external circuit and the protons pass through the proton exchange

membrane to cathode, where the proton meets the oxygen and electrons to form

water [6].

Mechanism of electron

transformation from bacterial cell to the anode is known by three ways,

firstly, using exogenous mediators (those present outside the cell) such as

thionine, methylene blue or neutral red and potassium ferricyanide. Secondly,

using mediators produced by the bacteria and finally by direct transfer of

electrons from the respiratory chain enzymes i.e. cytochromes, to the outer

cell membrane, which in turn is reduced and then leaving it in a reduced state

to shuttle the electrons to the electrode [7]. Geobacter

sulfurreducens, Geobacter metallireducens, and Rhodoferax

ferrireducens have been shown to produce the voltage in a mediator

less microbial fuel cell [8].

Hence, in order to study

metabolic activities of Rhizobium

leguminosarum in liquid broth, the microbial fuel cell could

be used as an effective tool. This study focuses on voltage generated by the

microbial fuel cell using fresh broth of Rhizobium leguminosarum with respect

to aeration and in absence of aeration. It could be an effective method to

determine the metabolic rate of cells in different physiological and

nutritional conditions.

MATERIAL AND METHODS

Pre-isolated and

pre-characterized culture tube of Rhizobium

leguminosarum from the soil samples Rajiv Gandhi

Biotechnology Centre, Nagpur, India premises was considered for inoculation of

fresh growth medium in laboratory of Department of Biotechnology at 16 December

2017.

Preparation of fresh culture

broth- The fresh nutrient medium was prepared

using Yeast Mannitol medium (YEMA Medium) which includes K2HPO4 0.05%, MgSO4

0.02%, NaCl 0.01%, Mannitol 1%, CaCO3 0.3%, Yeast 0.1% and Distilled

water. The contents of the medium are thoroughly mixed and allowed for

autoclaving at 121oC and 15 lb pressure. After the process of autoclaving

the medium, the medium is allowed to settle down to room temperature. This

process can be done more rapidly by placing the container of nutrient medium in

cool stream of water. Once the content is cooled then pH of the medium was

measured using digital pH meter. The optimum pH of this medium for Rhizobium

species should be 7 and hence it is necessary to confirm it. If the pH is not

neutral, then it is made neutral by adding strong acid like HCl or strong base

like NaOH. After gaining optimum pH, the broth was inoculated with 10%

inoculums of a Rhizobium leguminosarum and the content was

allowed to grow in well-aerated desktop fermentor or cotton-plugged glass

flask. Culture requires oxygen to multiply and grow efficiently; hence aerobic

fermentor is always preferable. The medium was allowed to grow for next 48

hours [9].

Microbial fuel cell construction- The MFC was constructed using two

screw-capped plastic bottles with the total working volume of 1 liter and it

served as anode (anaerobic) and cathode (aerobic) chambers. Both anode and

cathode chambers were connected with 1 cm in diameter and 5 cm long tube which

was filled up with salt bridge made of 1M Potassium Chloride (KCl) solution and

3% agar powder. Agar salt bridge acts as a barrier between the anode and

cathode chambers. The reason for using agars as salt bridge is to provide an

internal electrical connection between the chambers, while minimizing the

transfer of ions from the electrical environment [10]. Stainless

steel mesh of 500 gm and having diameter of 2 mm was used as anode and cathode.

Before the MFC operation, the electrodes were soaked in 0.1 M HCl solution for

a day to remove possible contamination and after the MFC operation the electrodes were washed with

0.1 M NaOH solution to neutralize the surface contaminants [11]. The electrodes were externally connected with 12 ohm resistance

using copper wire. This setup was prepared in triplicates in order to minimize

the errors in voltage recorded by the volt meter. Aeration of 600 ml per hour

is supplied to the cathode chamber using 1 liter injection syringe. Both the

bottles are screw capped properly in order to make both the chambers air tight.

Microbial fuel cell

operation- All the three microbial fuel cell setups are surface sterilized by

wiping with 70% alcohol and UV light exposure for 20 minutes. All the three

anode chambers of microbial fuel cell assemblies were filled with 400 ml

freshly prepared broth culture of Rhizobium leguminosarum in each chamber. After inoculation, the

assemblies are screw capped properly to maintain anaerobic conditions inside

the chamber. In cathode chamber, 800 ml of 1 M KCl solution was filled in all

the three assemblies. All the three assemblies are screw capped and aeration of

600 ml per hour is provided to the assemblies using 1 liter injection syringe.

Whatman filter is attached to the syringe before aeration in order to provide

sterile air flow [9].

RESULTS- A resistance of 12 ohm

is applied across cathodes and anodes of each assembly and voltage is recorded

in the voltmeter after every fifteen minutes. After one hour and 45 minutes,

the aeration is stopped and voltage is recorded after every 15 minutes for five

more times successively. Detailed data of recorded voltage in mV is summarized

in Table 1 and Fig. 1.

Table 1: Voltage

recorded by three microbial fuel cell assemblies after every 15 minutes

|

Time (Minutes) |

Voltage recorded by Set A (mV) |

Voltage recorded by Set B (mV) |

Voltage recorded by Set C (mV) |

|

0 |

90 |

50 |

70 |

|

15 |

130 |

70 |

100 |

|

30 |

130 |

90 |

120 |

|

45 |

160 |

108 |

127 |

|

60 |

185 |

130 |

135 |

|

75 |

184 |

145 |

150 |

|

90 |

184 |

180 |

182 |

|

105 |

184 |

180 |

182 |

|

AERATION |

STOPPED |

||

|

120 |

190 |

190 |

180 |

|

135 |

180 |

190 |

170 |

|

150 |

150 |

180 |

120 |

|

165 |

140 |

144 |

108 |

|

180 |

130 |

25 |

80 |

|

195 |

10 |

00 |

00 |

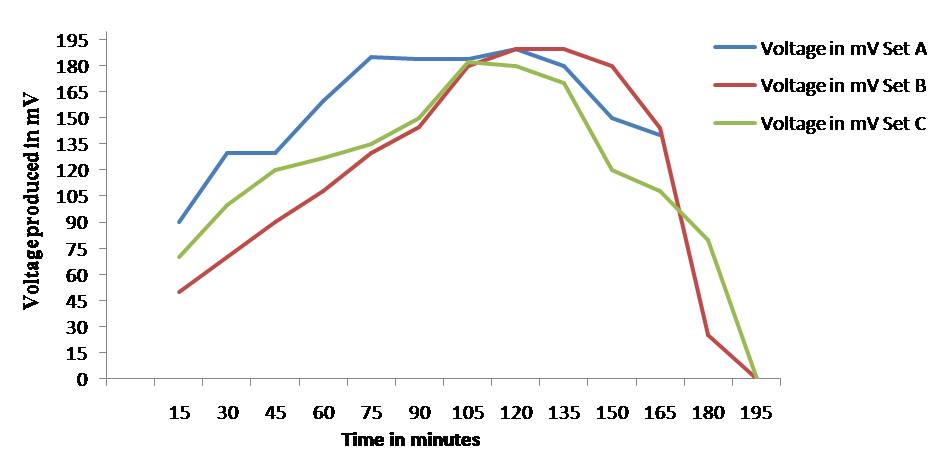

Fig. 1: Voltage produced by the culture of Rhizobium species with

respect to time

DISCUSSION- There has been an increase

in recent years in the number of reports of microorganisms that can generate

electrical current in microbial fuel cells. Although many new strains have been

identified, few strains individually produce power densities as high as strains

from mixed communities. Enriched anodic bio-films have generated power

densities as high as 6.9 W per m2 (projected anode area), and therefore are

approaching theoretical limits [12].

Power density, electrode

potential, coulombic efficiency, and energy recovery in single-chamber

microbial fuel cells (MFCs) were examined as a function of solution ionic

strength, electrode spacing and composition, and temperature. By the increasing

the solution ionic strength from 100 to 400 mM by adding NaCl increased power

output from 720 to 1330 mW/m2. Power generation was also increased

from 720 to 1210 mW/m2 by decreasing the distance between the anode and cathode

from 4 to 2 cm. The power increases due to ionic strength and electrode spacing

resulted from a decrease in the internal resistance. Power output was also

increased by 68% by replacing the cathode (purchased from a manufacturer) with

carbon cloth cathode containing the Pt loading [13].

It is a surprise to many

researchers that the most significant block to achieving high power densities

in MFCs is the system architecture, not the composition of the bacterial

community [14].

But power output by MFCs

has been consistently increasing over time. Improvements in system architecture

and operation have increased power densities from 1500 mW/m2 using

oxygen as the final electron acceptor at the cathode [15,16].

From Fig. 1 and Table 1 were observed that

the voltage produced by a freshly prepared broth of Rhizobium leguminosarum increases with time from its actual value to

180 - 190 mV with aeration of 600 ml per hour of sterile air in cathode chamber

in 105 minutes. But when the aeration is stopped completely, the voltage

produced by the culture in microbial fuel cell setup also decreases gradually

and it becomes zero after 180 minutes of starting the experiment. This change

in voltage with respect to time and with respect to aeration observed in very

similar pattern in all the three sets namely A, B, and C or microbial fuel cell

assembly. Hence, the graph of voltage against time gradually increases with

aeration and it gradually decreases from the peak when the aeration is stopped

in the cathode chamber of microbial fuel cell assemblies. The graph declines to

zero after 180 minutes.

The increase in the voltage generated by

microbial fuel cells with aeration suggests that metabolic rate of the growing

culture in the anode chamber increased with aeration, but after stoppage of

aeration, the metabolic rate of the bacterial culture decreased gradually due

to insufficiency of oxygen in the cathode chamber and as a result voltage

produced by it also decreased and it become zero after 195 minutes of

experiment when oxygen was completely exhausted in the cathode chamber. Zero

voltage recorded by microbial fuel cell assemblies suggests that the fuel cell

stops working and cells in the culture might have died.

CONCLUSIONS- From this study it could be concluded that

pre-isolated strain of Rhizobium leguminosarum is highly aerobic in nature and require enough oxygen to metabolize and reproduce.

The cell behavior or nutrient uptake studies of Rhizobium leguminosarum could be done using the voltage generated by

it in microbial fuel cell assemblies. The maximum voltage generated by a

freshly prepared broth of Rhizobium leguminosarum is in between 180 mV - 190 mV in microbial

fuel cell assembly.

In future, more work is required to be done

on the assembly for increasing this range of voltage. In addition to this

comparative study of different electrode material can also be done in order to

get an efficient and steady voltage for the sample organism.

ACKNOWLEDGEMENT- This investigation was fulfilled with the continuous support of

all the teaching and non-teaching staff of Rajiv Gandhi Biotechnology Centre,

Nagpur. I am especially thankful to Dr. Arti S. Shanware for her continuous

guidance and support while undergoing this research work.

CONTRIBUTION OF AUTHORS - All authors

equally contributed to this article.

REFERENCES

1.

Halvorson HO. Physiology of

sporulation, In I. C. Gunsalus and R. Y. Stanier [ed.], the bacteria. Academic

Press, Inc., New York, 1962; 4: 223-274.

2.

Halvorson HO. Sequential

expression of biochemical events during intracellular differentiation. Symp.

Soc. Gen. Microbiol., 1965; 15: 343-368.

3.

Murrell WG. Spore formation and

germination as a microbial reaction to the environment. Symp. Soc. Gen.

Microbiol., 1961; 11: 100-150.

4.

Microbial fuel cells. USA.

John Wiley and Sons, 2008; pp. 1-125.

5.

Imanaka H, Gillis JR,

Slepecky RA. Synchronous Growth and Sporulation of Bacillus megaterium. J Bacteriol., 1967; 93(5): 1624-1630.

6.

Sharma Suresh K, Bulchandani

BD. Comparative Study of Various Substrates and Microorganisms in a Laboratory

Designed Microbial Fuel Cell Int. J Res Chem Environ. 2012; 2(3): 168-174.

7.

Chaudhury SK, Lovely DR.

Electricity generation by direct oxidation of glucose in mediatorless microbial

fuel cells. Nat. Biotechnol., 2003; 21: 1229-1232.

8.

Bond DR, Lovely DR.

Electricity production by Geobacter sulfurreducens attached to electrodes,

Appl Environ Microbiol., 2003; 69: 1548-1555.

9.

Jakaria

Al-Mujahidy Sk, Hassan M, Rahman M and Mamun-Or-Rashid ANM Isolation and

characterization of Rhizobium sp. and determination of their potency for growth

factor production. Int. Res. J. Biotechnol., 2013; 4(7): 117-123.

10.

Patil

VD, Patil DB, Deshmukh MB, Pawar SH. Comparative study of bioelectricity

generation along with the treatment of different sources of wastewater.

International Journal of Chemical Sciences and Applications, 2011; 2(2): 162-168.

11.

Liu ZD,

Li HR. Effects of Bio and Abio-factors on Electricity Production in a

Mediatorless Microbial Fuel Cell, Biochem Eng J., 2007; 36(3): 209-214.

12.

Logan

BE. Exoelectrogenic bacteria that power microbial fuel cell. Nature reviews:

microbiology, 2009, pp. 375-381.

13.

Hong

Liu, Shaoan Cheng, Logan BE. Power generation in Fed- Batch Microbial Fuel Cell

as a function of ionic strength, Temperature, & Reactor Configuration. Environ.

Sci. Technol. 2005; 39 5488-5493.

14.

Kim BH, et al. Mediator-less biofuel cell.

U.S. Patent 5976719, 1999.

15.

Cheng

S, et al. Increased power generation in a continuous flow MFC with advective

flow through the porous anode and reduced electrode spacing. Environ. Sci.

Technol., 2006; 40: 2426–2432,

16.

Min B,

et al. Electricity generation using membrane and salt bridge microbial fuel

cells. Water Res., 2005; 39, 1675–1686.